Timothy Hefflinger is a William J. Clinton Fellow for Service with the American India Foundation (AIF). He has been working with the Snow Leopard Conservancy India Trust (SLC-IT) since September 2016. The following thoughts are his alone and do not necessarily represent the positions of SLC-IT or AIF.

A few months ago, I began looking into the history of SLC-IT’s involvement in the promotion of handicrafts in Ladakh. What I discovered was an interesting progression that sheds some light on a small segment of Development in the region. Throughout my research, the questions I had were “Who was involved?”, “What were they hoping to achieve?”, and “How exactly are these activities going to help Ladakhis?”

The earliest mention of handicrafts promotion that I could find came from 2003, from the Report on Community Based Eco-Tourism Planning in Ladakh. However, a SLC-IT newsletter also mentioned early involvement in handicrafts. It seems likely that the organization has had an interest in promoting handicrafts since the inception of the organization in the year 2000.

What strikes me about reading those early materials is that most villagers were interested in receiving training, but they expressed little or no interest in marketing or sales. I get the sense that many people from the villages that initially implemented the program (Rumbak, Skyu/Kaya, Yangthang, Ulley, Hemis Shukpachen, Ang, and Chilling) intended to sell their handicraft products locally. Some even mentioned building village shops from which to sell the handcrafted products. Also, the relative importance of handicraft products seemed to vary widely among the villages. It was simply not a priority for everyone. Critically, these early years included partnerships between SLC-IT and the Ladakh Ecological Development Group (LEDeG), highlighting the importance of cooperation in getting such projects off the ground.

Another fact that stood out was that there was an early emphasis on women. In the early days, handicrafts sales became linked with the Himalayan Eco-Cafés, which were operated mainly by women. In that way, handicrafts became a venue for women’s empowerment and the diversification of livelihoods in Ladakhi families. It wasn’t until around 2011 and 2012 that men’s involvement in crafts was explicitly mentioned in SLC-IT publications, and I believe this echoes the greater development trends of those years. It is during that time period (2000 to 2011) that farming perhaps became devalued in the regional economy in favor of tourism. As men’s traditional occupations shifted, it became clear that handicrafts was a viable income supplement for both men and women. SLC-IT has attempted to make their training inclusive of both sexes in the intervening years. I believe this is a positive development, as there are extraordinarily rich heritages of both men’s and women’s crafts in Ladakh.

Aside from local production and local sales (through the SLC-IT-supported Himalayan Eco-Cafés), there was not much formal programmatic work related to handicrafts until the year 2010. In that year, SLC-IT’s own Jigmet Dadul won a Rufford Small Grant for his proposed project: “Conservation of the Snow Leopard through Predator-Friendly Wool.” This small infusion of capital allowed training programs to begin in earnest. In November of 2010, Jigmet and the other SLC-IT staff launched the first of these training programs, titled “Using Natural Dyes for Handicrafts,” in the Nubra valley. As the SLC-IT newsletter from the time reports,

“The objective of this training program was to give the women’s group practical knowledge on the different natural dye processes and using natural and local raw materials.”

These themes (using local materials to produce and finish goods) have lived on in all SLC-IT programming.

The second official training held under the Predator-Friendly Wool program was focused mainly on knitting – the primary handicraft produced during this period. In fact, knitted items continue to sell well in the region, for obvious reasons. High-quality knitted items are simply a godsend in the frigid winter months, and SLC-IT’s emphasis on maintaining quality has been a hallmark of the group since the beginning.

Interestingly, I have noted an attitudinal shift regarding sales and marketing during this time period. In May 2011, I find the first written evidence that SLC-IT began committing to marketing and selling handicrafts products on behalf of villagers. The SLC-IT newsletter from the time period claims that

“The products will be sold in SLC-IT’s office for the initial year, since the number of products is still limited.”

I suspect that many villagers were finding it difficult to sell their products from their Homestays or in their Eco-Cafés, and SLC-IT’s involvement in sales was a pragmatic effort. The exposure that SLC-IT could offer was much higher than what villagers could expect on their own. This had some side-effects, as well: I see comparisons being made between the quality of goods between villages during this time. Perhaps this is a good thing. A little competition between villages encourages creating high-quality goods, and doing so consistently.

At the conclusion of the Predator-Friendly Wool project in July 2011, participants were asked to sign basic memoranda indicating their intent to produce certain amounts of goods within set periods of time. This represents perhaps one of the first concrete steps SLC-IT took to truly professionalize their handicrafts work. As the Rufford Small Grant Program was winding down, SLC-IT reported that

“Since it was the last phase in the project, the SLC-IT team emphasized continued support to the group, provided product orders and numbers were met with. …SLC-IT will be directly in contact with the community for procurement of their products and link them with marketing channels.”

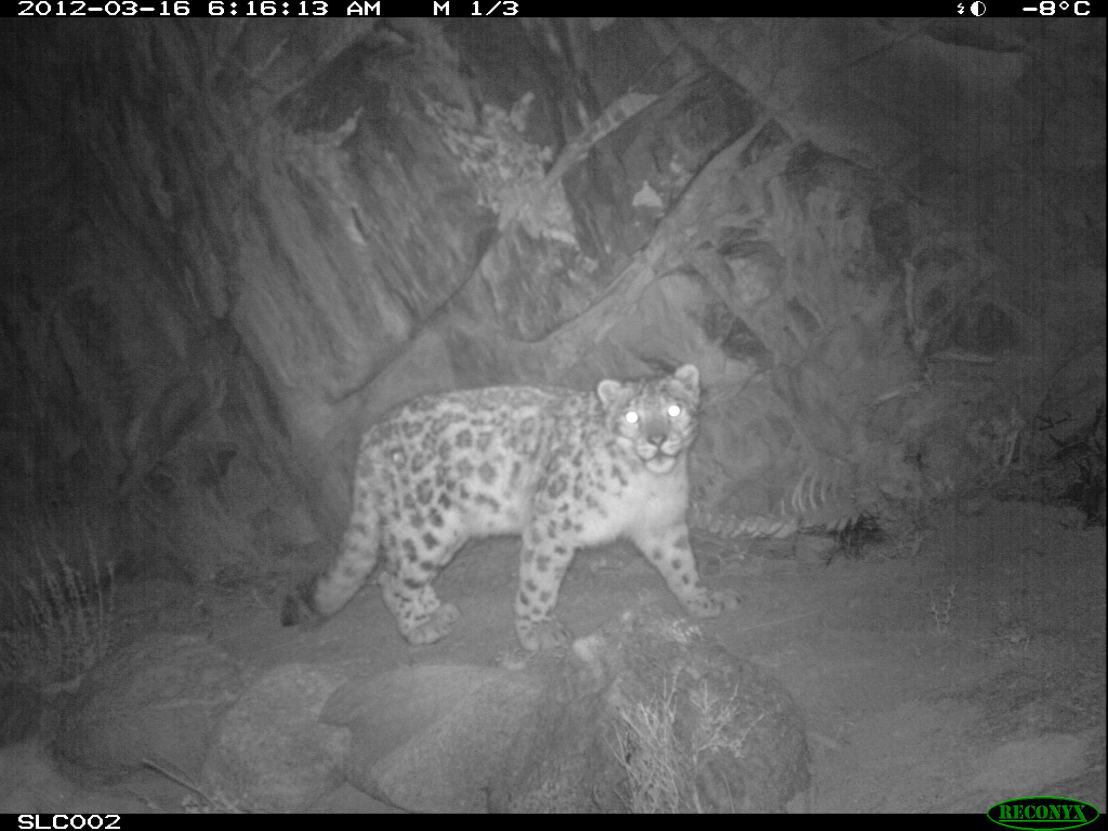

Shortly after this time, around October 2011, a new trend emerged in handicrafts, and I find it interesting. This trend is the “dry-needle-felting” style of creating small woolen figurines. As far as I know, this is not a local technique, and the needles necessary to produce the goods must be imported from Europe. In the dry-needling (or dry-felting) technique, those specialized needles are repeatedly punched into a woolen figurine to give it shape and definition. This process allows the creation of sometimes very striking figures, usually of local fauna. (As you might imagine, Snow Leopards are quite popular, and I’ve seen some amazing Ibexes as well. Though, now that I think about it, I’ve never once seen a wolf.)

This technique was introduced in an attempt to tap into those segments of the tourist markets that were flourishing on the sale of souvenirs. Unfortunately, I suspect this meant less energy and resources were invested in more-traditional crafts like knitting during this time, though knitted products continued to be important in sales.

This emphasis on production of dry-felted crafts was strong for many years thereafter. One newsletter from 2014 reported that

“the women of Karsha Village in Zanskar have continued the legacy of their ancestors by manufacturing and selling large numbers of woolen caps, socks, gloves, shawls, and carpets. In order to help these women diversify and further perfect their craft, SLC-IT conducted a two-day handicraft training that focused on the new technique of dry needle-felting. The women were very excited at the prospect of learning to make animal figurines using the new technique.”

In any case, dry-felted items will likely continue to be produced and sold for external markets. As long as it continues to add income to Ladakhi families, this is a good thing.

However, in late 2014, the Director of SLC-IT, Dr. Tsewang Namgail, began calling for greater diversity in the types of handicrafts produced, and villagers seemed to agree with him. The newsletter from the time reports that

“Dr. Namgail suggested diversifying the handicraft products. Possibilities of making woolen rugs, socks, caps, gloves, and sweaters for tourists were discussed. He emphasized on the quality rather than the quantity of products.”

Further, the newsletter reported that “villagers from Tukla, Liktse, Hemya, Khatpu and Tarchit requested training in other handicrafts.”

In the years between then and now, SLC-IT has been working to expand their influence in handicrafts throughout the region. Earlier years had seen the expansion of training programs throughout first the Sham valley, then the Nubra valley, then to Zanskar, and finally to the Rong valley. SLC-IT has also introduce standard sizes for their handicrafts, which enables standard pricing and honest quality comparisons among craftspeople. All of these efforts have paid off as the program gains eminence. Additionally, in late 2015 and 2016, the introduction of wood-carving and stone-etching in SLC-IT training has greatly expanded the reach of the program. I find these latter developments to be particularly encouraging.

In late 2016 I had the opportunity to attend a handicrafts training conducted by SLC-IT in Yangthang village. The participants divided themselves into three groups by which craft they hoped to practice. There was a sizable group of men and women who dedicated themselves to improving their dry-felting techniques over the course of the three-day workshop, but there were also two smaller groups of (mostly men) who worked on wood-carving and stone-etching. These latter two crafts have very deep histories here in Ladakh, especially the stone-etching. I was thrilled to see the inter-generational nature of these crafts, with many young people learning from their elders. This is the true essence of crafts-work, and I was happy to see that SLC-IT was encouraging the transmission of knowledge and skill to the younger generation.

In conclusion, I have found that the SLC-IT Handicrafts Program has taken many turns over the years. I also believe that it is continually improving, and becoming more adept at increasing livelihoods for rural villagers every year. I believe that as long as SLC-IT maintains its current emphasis on quality, using local materials, and investing time and energy in skills training, the program will be a success. I also believe that there may be sufficient interest among participants to create a producer co-operative to further their goals of marketing and sales. Only time will tell if that idea has any merit, but in any case, I’m grateful to have witnessed Himalayan Handicrafts in action.

– By Timothy Hefflinger